Our History

S & L Spindles has been in business for decades, producing wood spindles and deck products for wholesale markets up and down the East Coast. We were formed in 1989 by the late Elam Lapp and his right-hand man, David Smucker. In December of 2019 we came under the ownership of a group of six men– Melvin Lapp, Elmer Lapp, Raymond Petersheim, John Stoltzfus, Benuel Kauffman, and Matthew Byler.

Our History

S & L Spindles has been in business for decades, producing wood spindles and deck products for wholesale markets up and down the East Coast. We were formed in 1989 by the late Elam Lapp and his right-hand man, David Smucker. In December of 2019 we came under the ownership of a group of six men– Melvin Lapp, Elmer Lapp, Raymond Petersheim, John Stoltzfus, Benuel Kauffman, and Matthew Byler.

How we’ve grown

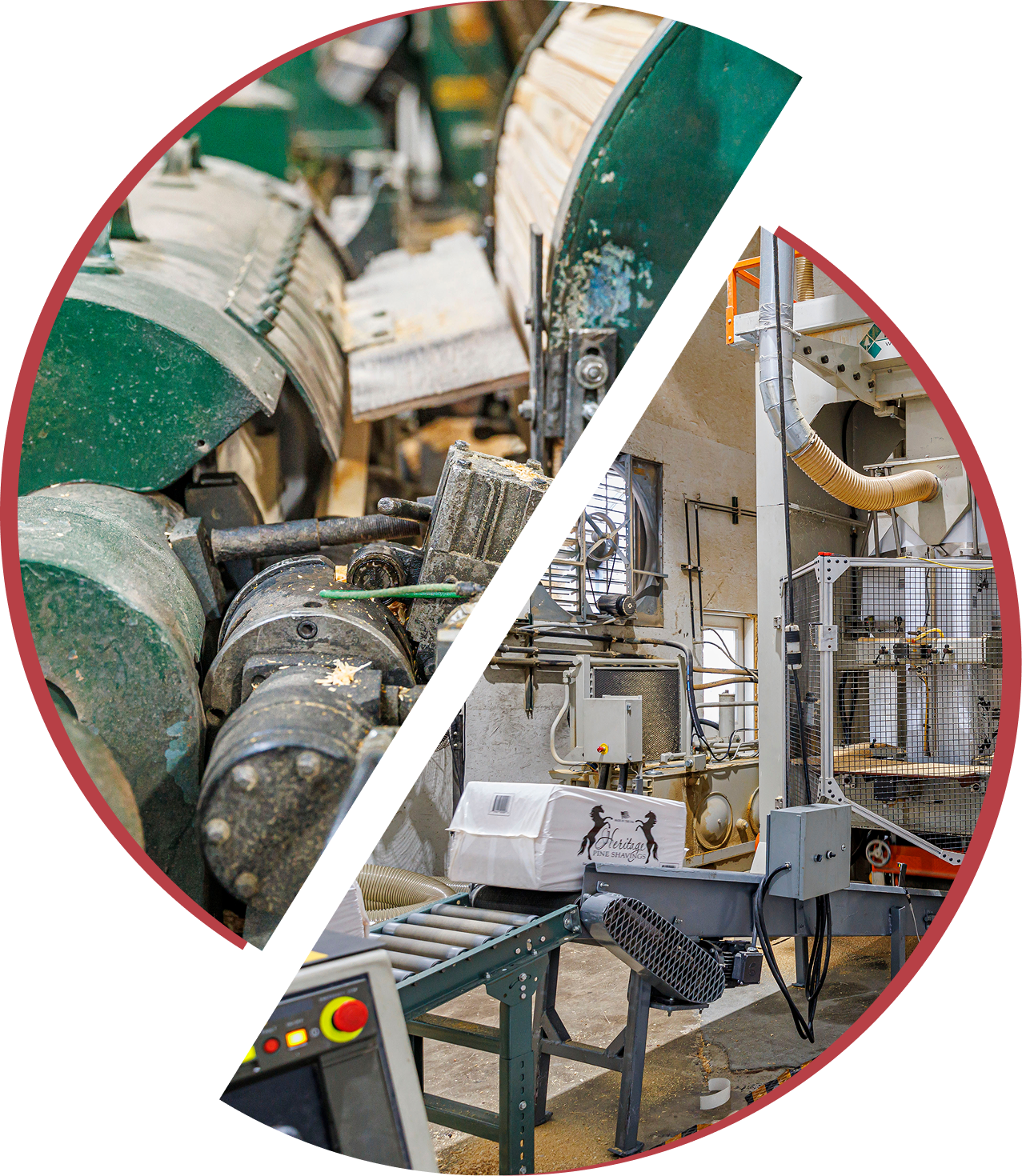

In 2004 we purchased a large lot of equipment from Barrette Wood in Bulls Gap,TN. The acquisition of this equipment allowed us to expand our product lines, greatly increase production, and tap into the big box market. Over time, many improvements have been made to this department. The most notable is a Woodeye computerized grading system added in 2018 that enables us to run up to 250 balusters per minute.

Due to tight supply chains in 2021, we were approached by customers asking us to produce pallet boards and stringers. While starting with machinery we had, in the next few years we invested heavily in machinery specifically for pallet cut stock manufacturing. A Pendu Board Splitter came in November of 2021. The most recent was a ABSAMS and TS300 Stacker from Pallet Machinery Group in December of 2024. Currently most of one entire work area is dedicated to Pallet Cut Stock with production capabilities around 60,000 bf per day.

Heritage Pine Shavings

Turning Wood Waste into Premium Animal Bedding

As a wood manufacturer, there will inevitably be waste. At S&L Spindles, we found a way to turn wood waste into a useful product– animal bedding. For the first 25 years a small part of this product was bagged by hand for purchase by local customers. In May of 2023, we purchased a Rethceif VC-3030 Compression Bagger, capable of producing 4-5 bales per minute. A stacking system was added a year later, and our shavings are now sold to farm supply stores and horse enthusiasts across the Northeast and Mid-Atlantic region.

Overcoming challenges

We have faced some adversity in the past few years, including the Covid 19 Pandemic, which brought much uncertainty to our industry, but ultimately presented opportunities for growth.

On June 27th, 2023, S & L suffered a major fire, resulting in the loss of approximately 10% of our building space and one complete manufacturing area. In the aftermath of this devastating event, we were humbled by the support from our employees and their families, our key vendors, and the local community. Many ideas were discussed lengthwise and crossways, and after a lot of hard work, machinery was replaced or rebuilt. Finally nine months later the work area was back in production.

Our commitment to continuous improvement

As the company grew in size and production, we saw a need to improve the safety, working conditions, workflow, and general organization of our facility. In March of 2018, we hired our first Continuous Improvement coach. Much time was spent on employee training, implementation of lines, signs and labels, and revamping work areas. Built around the 6 S’s– sort, set in order, shine, standardize, sustain, and safety– this system continues to be a key part of our operation.The greatest return is the employee engagement and the ideas they bring to the table.

Innovation today

keeps us thriving tomorrow

keeps us thriving tomorrow

With a history rich in innovation, S&L Spindles remains committed to continuous improvement through investment in our hardworking team, equipment, and systems. With 30+ employees, three late model 12” Weinig Moulders, three trimsaws, a Woodeye grading system, multiple stacking and packaging systems, and a current annual production of 35,000,000 board feet, we will continue to accurately and efficiently provide the quality products our customers need for years to come.